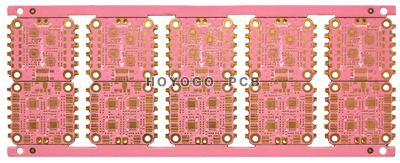

PCB is an extremely important basic assembly component of electronic equipment, and it is widely used in various electronic equipment such as household appliances, instrumentation, and computers. So after getting the PCB, if we want to extend the service life of electronic products, how should we maintain PCB?

1. Before maintenance, please check the entire PCB for bulging or leakage of electrolytic capacitors. If these conditions occur, you need to replace the new PCB in time.

2. When performing random checks on the electrolytic capacitor capacity, if the electrolytic capacitor capacity is much lower than the nominal capacity, it needs to be replaced. The service life of the electrolytic capacitor is generally about ten years. If it reaches a certain number of years, please replace it to ensure that the PCB can maintain the best working performance.

3. The dust on the PCB needs to be cleaned every three months. It is necessary to clean the dust on PCB every three months. When cleaning, you cannot use water for cleaning. Please use special plate washer water, hydrogen peroxide or thinner to clean. The deoxidation effect is also very good. After washing, you need to use a hair dryer to dry it in time, do not let it dry by itself, otherwise it will cause varying degrees of damage.

4. When the PCB is stored, try not to directly touch the surface between the board and the board to avoid scratches or discoloration.

5. If high-power devices are coated with thermal grease, please check whether the thermal grease is dry or solid. If you find dry solids, please remove them, and then re-apply new thermal silica gel. This is to prevent the PCB from burning out and causing the device to fail to operate normally.

HOYOGO is an international, professional and reliable PCB manufacturer. With our own production capacity, we can provide you with one-stop service from small, medium to mass production. HoYoGo can offer board of HDI, gold finger, hard gold, flexible, rigid-flex, metal base, quick-turn around and PCBA. The layer is normally from 1 to 28layer. The base material also depends on the requirement, it can be KB or shengyi, etc.